CLEAN ENERGY CHOICES FOR THE FUTURE

35th IMI Industries

Sustainable developing innovation for society, the company focuses on developing high-quality products and services.

IMI Industries Business

Energy

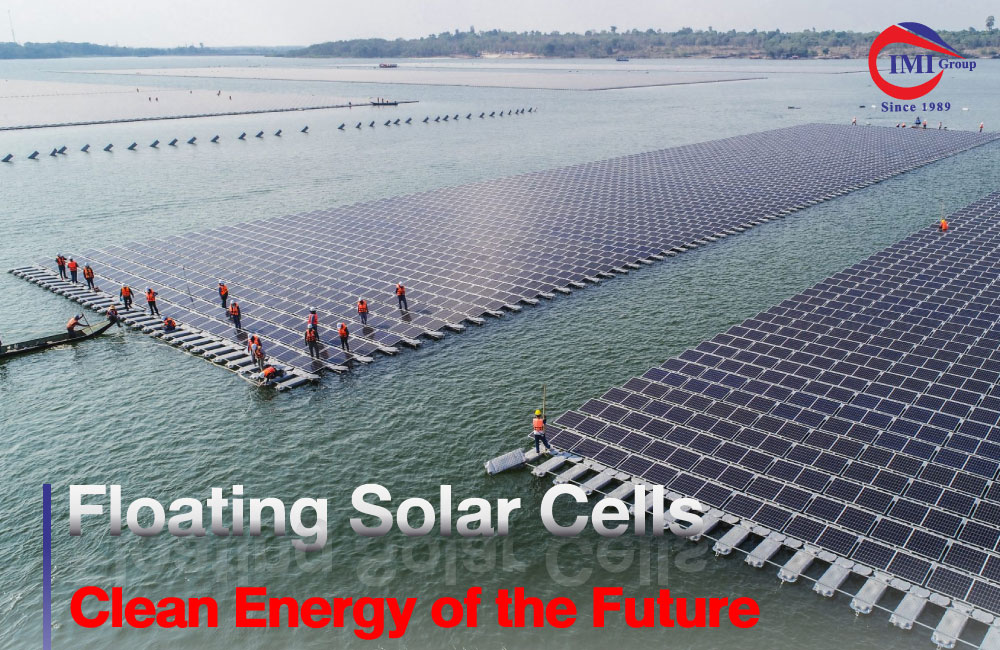

Renewable Energy

Education & Enterprise

IMI Industries

As a leading energy industry player with 35+ years of proven experience, IMI Industries delivers comprehensive engineering & EPC services across all sectors, with a strong focus on clean energy initiatives.

IMI Industries is committed to developing high-quality, sustainable products.

Our Portfolio

Contact us! for any queries about the installation process of EV Chargers and EV Stations

IMI Industries provides consultation & Installation for Enterprises, Hotels, Resorts, Restaurants, etc.

Contact us! for any queries about the installation process of solar cells

IMI Industries provides consultation and Solar cells installation for projects, and factories. and business owners, etc.

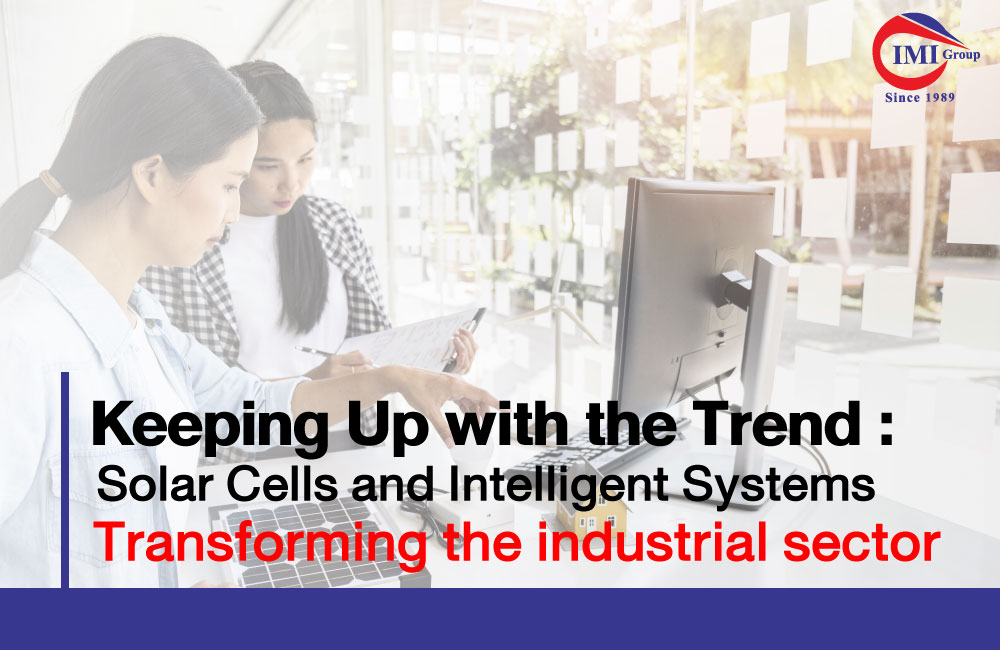

News

Business Partners

OFFICE

- Headquarters : Bangkok

- Branch Office : Rayong

- Technical services team:

-Northeast Khon Kaen/Roi Et/Nakhon Ratchasima

-Northern Region Lamphun/Phitsanulok

-Southern Region Phetchaburi/Surat Thani